Bases

Bases

Bases can be either onshore of offshore and function as a port or wet storage location.

When you add a base to your case, you have a variety of inputs you can use to determine the location of your base and how it functions within the simulation.

Base inputs

These inputs are for a port. If you are editing an offshore base, the only inputs that are applicable are the location and weather.

Parameters

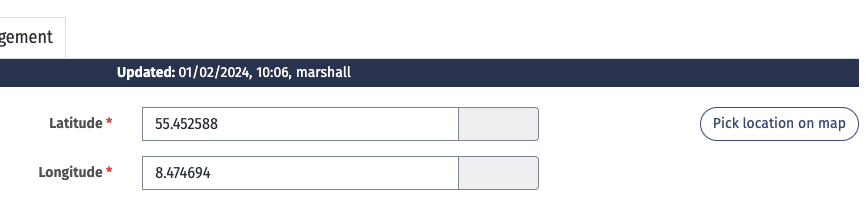

Under parameters, you can adjust the location of your port.

You can set the location of your port on the map by clicking Pick location on map. Then, click on the map to place the port.

- Latitude and Longitude: Define the location of the port.

- Number of repair slots: Define the number of available repair slots in the port used for repairing a floating turbine.

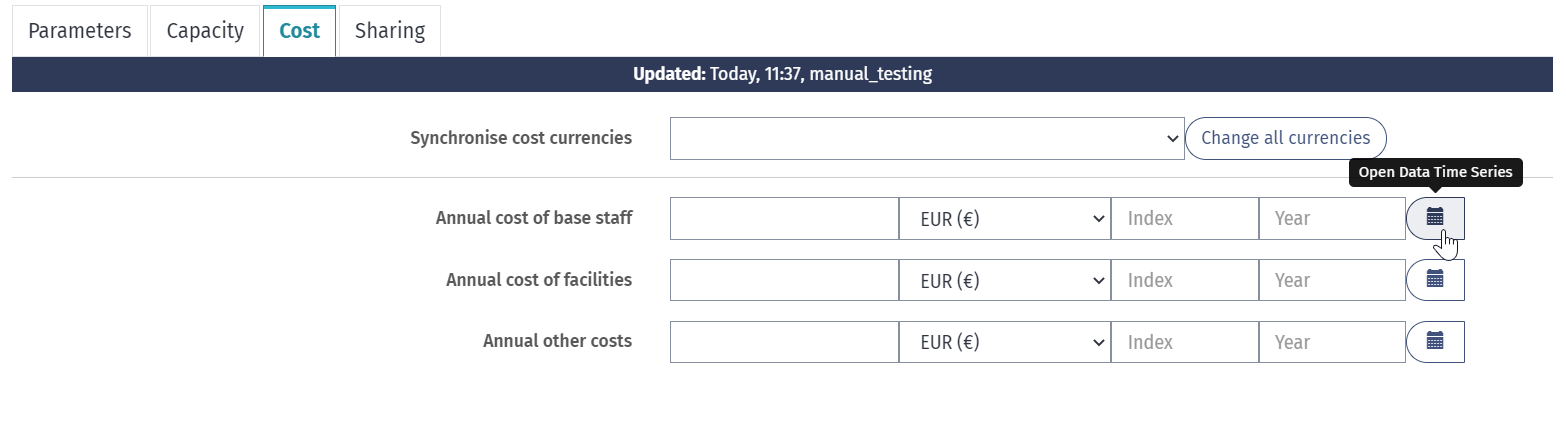

Cost

This section is not necessary to run a simulation but allows you to include the cost in your outputs for reference. The costs that you can include here are currencies, annual cost of base staff, annual cost of facilities and annual other costs.

Data time series

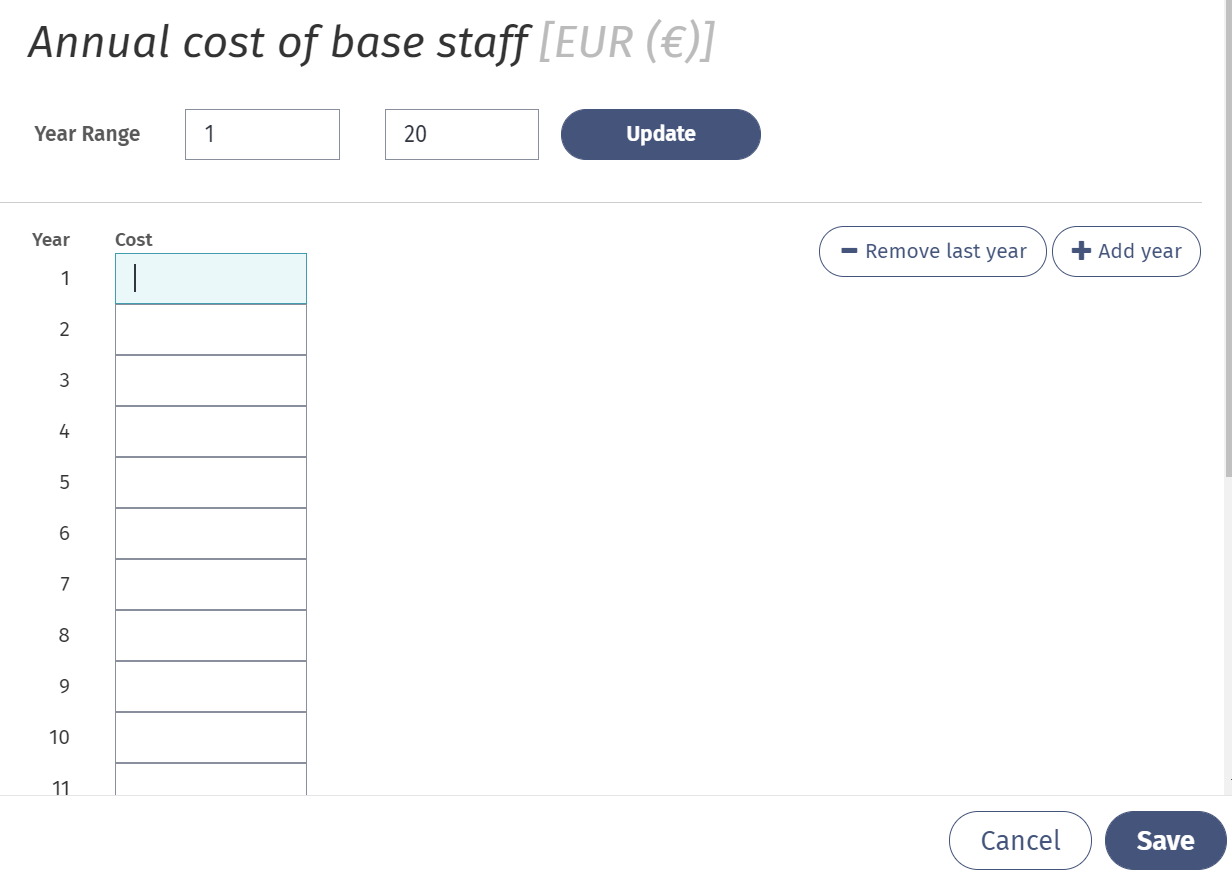

You can also add a cost time series, so your cost differentiates by year. This is done by clicking Open Time Data Series.

Set your year range starting with 1 and how many years you want to simulate and click Update. The actual year is derived from the operational start year on the assets (if your operational start year is set to 2021-xx-xx, year 1 is 2021, year 2 is 2022, etc.), to which you can add the cost per year.

Weather

Choose the weather file that applies to the base. There are two ways you can load this file: using imported weather data or ERA5 weather data.

See our Add weather page for details on how to add weather to a base

Apply everywhere applies the weather file to all bases and assets currently added to your case. This action will overwrite any existing weather data.

Inventory management

Add components to your base to model stock levels and component transport and assembly. Learn more about this feature on our Inventory management page.

Route planner

Custom Route: Define the route a vessel must follow when sailing from the port to the destination. Learn more about this here.

Inventory management

Inventory management modelling follows these criteria:

- Component loadoff (i.e., restocking) is paused when the maximum storage capacity or total restock limit is reached.

- Component loadout (i.e., transfer to another base or the installation site) is paused when stock levels for one or more of the necessary assemblies or components hit zero.

- Assembly tasks have the following effects:

- Input components (e.g.,

Tower lower,Tower middle, andTower upper) create storage space for more of the constituent components. - Output components (e.g.,

Tower complete) occupy storage space for that component type.

- Input components (e.g.,

Stock levels

There are 3 main ways to configure stock levels:

- If a base starts out with some components, but not enough for all your assemblies and installations:

- Set an initial stock level below the total necessary for assembly and installation.

- Then, there are two options:

- Set a restock rate.

- Create transportation tasks for restocking.

- Then, there are two options:

- Set an initial stock level below the total necessary for assembly and installation.

- If a base starts out empty and you want to model the component transport to the base:

- Don't set an initial stock level.

- Then, create transport tasks for restocking.

- Don't set an initial stock level.

- If your base contains enough components at the start of the project for all your assemblies and installations, or you don't want to model transport of components:

- Set an initial stock level equal to or greater than the total necessary for assembly and installation.

- Then, neither set a restock rate nor create transport tasks for restocking.

- Set an initial stock level equal to or greater than the total necessary for assembly and installation.

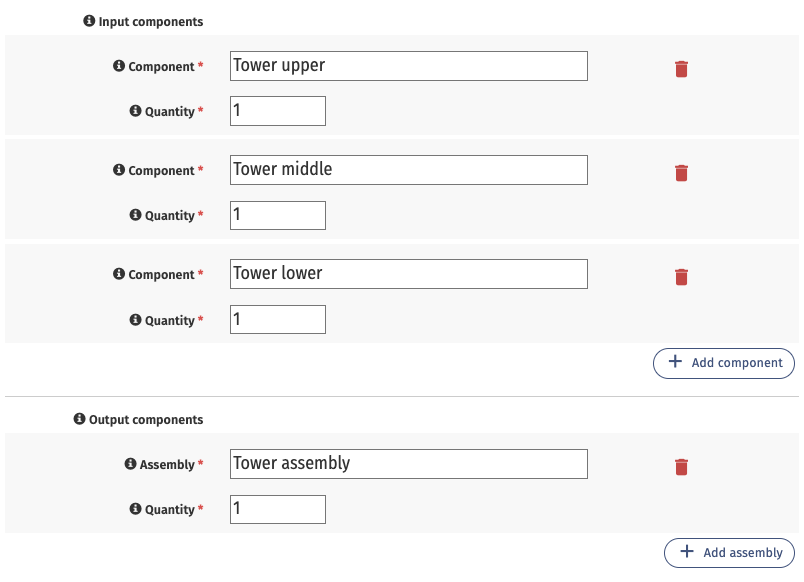

Component quantities

The number of asset tasks (e.g., transport, assembly, and installation) created in your simulation are proportional to the number of asset instances in your case. For example, if you have 100 WTGs instances, there will be 100 transport tasks, 100 assembly tasks, and 100 installation tasks.

The same applies to the input and output components you add to an asset task as part of inventory management: they will replicate across each instance.

The effect of this is that you only need to add the number of input or output components for a single asset.

Some examples:

- For a WTG tower assembly task:

- Add 1

tower (lower), 1tower (middle), and 1tower (upper)as inputs - Add 1

tower (assembly)as an output.

- Add 1

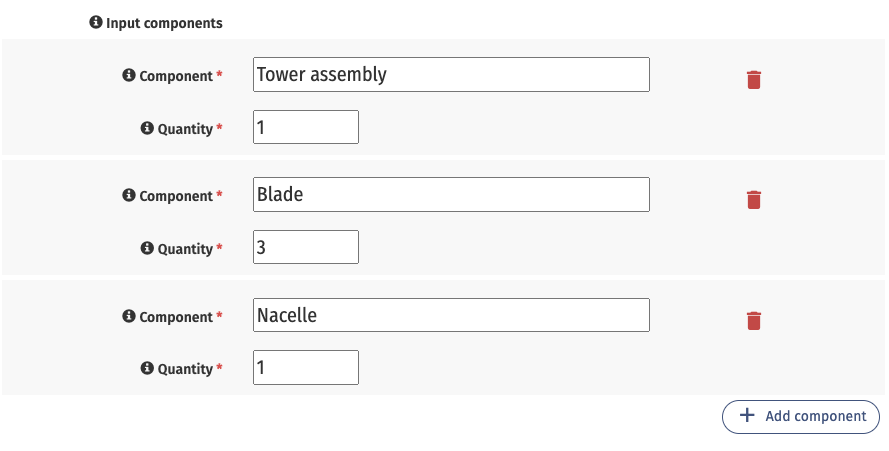

- For a WTG installation task:

- Add 3

blade, 1nacelle, and 1toweras inputs.

- Add 3

Logistics carry tasks, not components!

Increase the Maximum capacity parameter in the logistic's Capacity tab to increase the number of tasks it can carry out at one time. For example, if you have a transport task with 1 nacelle component, you can set the Nacelle COTV’s Maximum capacity to 3. It will then carry 3 transports tasks—-and therefore 3 nacelles-—in one trip.

Inventory management parameters

| Parameter | Required | Description |

|---|---|---|

| Component name | x | A descriptive name for your component. You will reference this in the asset tasks you create. |

| Set stock levels | Check this box to define Maximum stock level and Initial stock level values. | |

| Maximum stock level | The maximum number of this component that the base can stock. | |

| Initial stock level | Number of the component available in the case one the simulation start date defined on the Simulate tab of your case. This value must be equal to or lower than the Maximum stock level. |

|

| Set a fixed restock rate | Check this box to define a custom Restock rate value. | |

| Restock rate | Automatically restock components at the base at a fixed rate. Restocking occurs without an assigned task and independently of weather limitations. Restocking pauses when the base is at maximum capacity for this component. |

|

| Total restock limit | The maximum number of components that will arrive through restocking. Without setting this parameter, components will continue to arrive through restocking, even when the base has enough components to construct all the assets in your case. |

|

| Set a custom restock start date | Check this box to define a Custom restock start date. By default, restocking begins on the simulation start date defined in the Simulate tab of your case. | |

| Custom restock start date. | This date must be on or after the simulation start date defined in the Simulate tab of your case. |